Compact Wheel Loaders

Cat 906 Compact Wheel Loader

-

Maximum Gross Power74.7 hp

-

Engine ModelCat C2.8*

-

Maximum Engine Speed2550 rpm

-

Maximum Gross Power2400 r/min

Engine

- Maximum Gross Power

- 74.7 hp

- Engine Model

- Cat C2.8*

- Maximum Engine Speed

- 2550 rpm

- Maximum Gross Power

- 2400 r/min

- Maximum Gross Power

- 74.7 hp

- Maximum Gross Power

- 74.3 hp

- Maximum Gross Power

- 75.3 mhp

- Rated Net Power

- 2400 r/min

- Rated Net Power

- 72.7 hp

- Rated Net Power

- 72.1 hp

- Rated Net Power

- 73.1 mhp

- Maximum Gross Torque

- 222 lb/ft

- Maximum Gross Torque

- 221 lb/ft

- Maximum Net Torque

- 218 lb/ft

- Maximum Net Torque

- 217 lb/ft

- Displacement

- 171 in³

- Bore

- 3.54 in

- Stroke

- 4.33 in

- Note

- Advertised power is tested per the specified standard in effect at the time of manufacture.

- Note

- Net power advertised is the power available at the flywheel.

- Note

- *Two Cat C2.8 engine emission options are available: 1) Meets U.S. EPA Tier 4 Final, EU Stage V. 2) U.S. EPA Tier 3 and EU Stage IIIA equivalent. Tier 3 engine specs are 0.3 kW/0.4 hp more gross power (SAE J1995), 0.2 kW/0.3 hp on net power (SAE J1349) an

- Note

- #Maximum gross and net torque measured at 1,600 rpm.

Weights

- Operating Weight

- 12628 lb

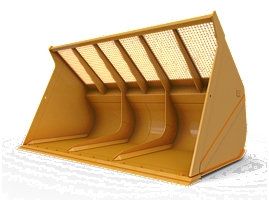

Buckets

- Bucket Capacities

- 0.75-1.55 m³ (1.0-2.0 yd³)

- Bucket Capacities

- 0.80-1.35 m³ (1.0-1.7 yd³)

- Bucket Capacities

- 1.25-1.55 m³ (1.6-2.0 yd³)

- Multi

- 0.75-1.1 m³ (1.0-1.4 yd³)

- Note

- Bucket selection must be made with an understanding of the material density and application to ensure machine stability is maintained within the tipping loads stated per model and configuration.

- Note

- Bucket capacities stated include BOCE, in line with ISO 7546.

Service Refill Capacities

- Fuel Tank

- 18.5 Gal

- Cooling System

- 3.2 Gal

- Engine Crankcase

- 2.3 Gal

- Axles

- 2.3 Gal

- Axles

- 2.3 Gal

- Hydraulic System

- 17.8 Gal

- Hydraulic Tank

- 11.8 Gal

- Transmission

- 0.6 Gal

- Note

- No Diesel Exhaust Fluid (DEF) fluid needed on this size engine.

Axles

- Front

- Fixed (standard) Locking Differential (optional)

- Rear

- Fixed (standard) Locking Differential (optional)

- Note

- Oscillation of ±11 degrees via hitch between front and rear frames.

Steering

- Steering Articulation Angle

- 39 °

- Maximum Flow

- 12.3 gal/min

- Maximum Working Pressure

- 3336 psi

- Steering Cycle Times

- 2.8 s

- Number of Steering Wheel Turns

- 3.25 turns or 4.00 turns

Transmission

- Forward and Reverse

- 6 mile/h

- Forward and Reverse

- 6 mile/h

- Forward and Reverse

- 10.5 mile/h

- Forward and Reverse

- 12 mile/h

- Forward and Reverse

- 25 mile/h

- Note

- #Factory default shown, can be adjusted to any speed up to 19 km/h (12 mph).

- Note

- *Creep function not available in this gear or above.

- Note

- **Max speed dependent on model and configuration (standard vs. high speed transmission).

- Note

- ***Reverse is 30 km/h (19 mph).

Tires

- Tire Size

- *405/70 R18 SPT9

- Tire Size

- 405/70 R18 Powerloads

- Tire Size

- 340/80 R18 XMCL/Bibload

- Tire Size

- 340/80 R18 TRI 2

- Tire Size

- 40X14-20 TL, SM/TR

- Tire Size

- 340/80 R18 Duraforce

- Note

- *This tire has been used for all dimension, stability and performance data.

- Note

- Other tire choices are available. Contact your Cat dealer for details.

- Note

- In certain applications, the loader’s productive capabilities may exceed the tire’s tonnes-km/h (ton-mph) capabilities.

- Note

- Caterpillar recommends that you consult a tire supplier to evaluate all conditions before selecting a tire model.

Cab

- ROPS

- ISO 3471:2008

- FOPS

- ISO 3449:2005 Level II

- Note

- Canopy and cab, Rollover Protective Structures (ROPS) are available worldwide. Canopy not available in EU.

- Note

- The declared dynamic operator sound pressure levels per ISO 6396:2008*, when properly installed and maintained, is 71 dB(A).

- Note

- *Measurements were conducted with the cab doors and windows closed.

- Note

- The labelled sound power level for the CE marked configurations when measured according to the test procedure and conditions specified in 2000/14/EC is 101 dB(A). 99 dB(A) Low Sound – Option available.

Loader Hydraulic System

- Main Relief

- 3408 psi

- Main Relief

- 21 gal/min

- Main Relief

- 32 gal/min

- Main Relief

- 3408 psi

- Main Relief

- 12 gal/min

- Hydraulic Cycle Time

- 2.2 s

- Hydraulic Cycle Time

- 5 s

- Hydraulic Cycle Time

- 1.6 s

- Hydraulic Cycle Time

- 2.8 s

- Note

- * Maximum flow stated, actual flow delta could be 6% from data shown. Also adjustable from 20% to 100% of maximum flow through display.

Dimensions - With HPL-V Coupler - Approximate#

- Height

- 8.08 ft

- Height

- 8.67 ft

- Height

- 1.58 ft

- Height

- 1 ft

- Length

- 17.58 ft

- Length

- 4.58 ft

- Length

- 3.58 ft

- Length

- 7.08 ft

- Clearance

- 8.25 ft

- Clearance

- 9.5 ft

- Clearance

- 9.92 ft

- Height

- 10.67 ft

- Height

- 13.5 ft

- Reach

- 2.42 ft

- Carry Height

- 1.08 ft

- Dig Depth

- 0.33 ft

- Width

- 6.17 ft

- Width

- 4.67 ft

- Turning Radius

- 14.17 ft

- Width

- 6.08 ft

- Turning Radius

- 12.92 ft

- Turning Radius

- 6.75 ft

- Rack Angle at Full Lift

- 56°

- Dump Angle at Full Lift

- 45°

- Rack Angle at Carry

- 51°

- Departure Angle

- 30°

- Articulation Angle

- 39°

- Operating Weight

- 12632 lb

- Tipping Load

- 9760 lb

- Tipping Load

- 8225 lb

- Operating Weight

- 12240 lb

- Tipping Load

- 7748 lb

- 80

- 5211 lb

- Note

- *Vary with bucket

- Note

- **Vary with tire

- Note

- ^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), 0.95 m3 (1.2 yd3) general purpose bucket.

- Note

- ^^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), class II carriage, 1220 mm (4 ft) tines (500 mm [20 in] load center).

- Note

- †Full compliance to ISO 14397-1 (2007) Sections 1 thru 6 (fork 500 mm [20 in] load center), which requires 2% verification between calculation and testing.

- Note

- ††Full compliance to EN474-3 and SAE J1197.

- Note

- #HPL-A weight, tipping and rated loads are within 1% of the HPL-V.

- Note

- Dimensions listed are for a machine configured with standard cab, heater, 20 km/h (12 mph), standard guarding, 80 kg (176 lb) operator, full fluids, SPT9EM 405/70 R18 tires and 0.95 m3 (1.2 yd3) general purpose bucket with bolt-on cutting edge or a class

- Note

- Note: Goodyear POWERLOAD® tires can add up to approximately 140 kg (305 lb) to the full turn tip load and reduce vertical height by approximately 25 mm (1 in) compared to SPT9.

- Length

- 3.5 ft

- Tipping Load

- 6514 lb

Dimensions - With SSL Coupler - Approximate

- Height

- 8.08 ft

- Height

- 8.67 ft

- Height

- 1.58 ft

- Height

- 1 ft

- Length

- 18.17 ft

- Length

- 4.58 ft

- Length

- 3.58 ft

- Length

- 7.08 ft

- Clearance

- 7.83 ft

- Clearance

- 9.5 ft

- Clearance

- 9.92 ft

- Height

- 10.67 ft

- Height

- 13.83 ft

- Reach

- 2.67 ft

- Carry Height

- 1.17 ft

- Dig Depth

- 0.25 ft

- Width

- 6.17 ft

- Width

- 4.67 ft

- Turning Radius

- 14.67 ft

- Width

- 6.07 ft

- Turning Radius

- 12.92 ft

- Turning Radius

- 6.75 ft

- Rack Angle at Full Lift

- 51°

- Dump Angle at Full Lift

- 50°

- Rack Angle at Carry

- 46°

- Departure Angle

- 30°

- Articulation Angle

- 39°

- Operating Weight

- 12863 lb

- Tipping Load

- 8613 lb

- Tipping Load

- 7220 lb

- Operating Weight

- 12434 lb

- Tipping Load

- 7359 lb

- 80

- 4970 lb

- Note

- *Vary with bucket

- Note

- **Vary with tire

- Note

- ^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), 0.95 m3 (1.2 yd3) general purpose bucket.

- Note

- ^^Horizontal Pin Lock Coupler (HPL-V) or Vertical Pin Coupler (SSL), class II carriage, 1220 mm (4 ft) tines (500 mm [20 in] load center).

- Note

- †Full compliance to ISO 14397-1 (2007) Sections 1 thru 6 (fork 500 mm [20 in] load center), which requires 2% verification between calculation and testing.

- Note

- ††Full compliance to EN474-3 and SAE J1197.

- Note

- #HPL-A weight, tipping and rated loads are within 1% of the HPL-V.

- Note

- Dimensions listed are for a machine configured with standard cab, heater, 20 km/h (12 mph), standard guarding, 80 kg (176 lb) operator, full fluids, SPT9EM 405/70 R18 tires and 0.95 m3 (1.2 yd3) general purpose bucket with bolt-on cutting edge or a class

- Note

- Note: Goodyear POWERLOAD® tires can add up to approximately 140 kg (305 lb) to the full turn tip load and reduce vertical height by approximately 25 mm (1 in) compared to SPT9.

- Tipping Load

- 2818 kg

- Length

- 4.33 ft

Sustainability

- Recyclability

- 93%

-

ELECTRICAL

- Product Link™

- Service (Electronic Technician™)

- Lights, roading, front halogen

- Lights, rear stop and turn, LED

- Cab mounted fuse panel

- Battery disconnect switch

- Battery, heavy duty, 12V, 90Ah and 1,000 CCA

- Alternator, 100 amp sealed

-

HYDRAULICS

- Motor, single drive with dedicated implement and steering pumps

- Multi-function lift and tilt with loader arm float

- Joystick, single lever, single auxiliary roller

- Implement valve, pressure compensated

- Hystat displacement pump, infinitely variable

- Caterpillar HYDO™ Advanced 10 hydraulic oil

- Coupler/pin on attachment ready

- Demand cooling fan, hydraulically driven

- Dead engine lower, lift valve, manual

- Electro-hydraulic, fully proportional controls

- Hydraulic pilot shut off switch, in cab

-

OPERATOR ENVIRONMENT

- Cab

– Doors (2), fixed glass

– Wipers, front and rear, full front coverage

– Windshield, front single piece

– Window, rear heated

– Radio ready, speakers and wiring

– Air vents, (4) screen, (7) directional

– Heating, mechanical control unit

– Sun visor, solid, front full width

– Interior light (incandescent) - Seat, manual height adjustment, (cab) fabric with adjustable left arm rest, (canopy) vinyl

- Joystick, seat mounted, standard multifunction

– FNR, auxiliary roller, speed range select, continuous flow, differential lock, horn

– Arm rest, padded right, multiple position vertical height - Display, analog and digital

– Gauges (2), hydraulic oil, engine coolant

– Digital with soft touch buttons – fuel level, speed range, speedometer, service hour meter, service/maintenance information, hydraulic and power train performance and aggressiveness settings, security passcode (multiple languages) - ROPS/FOPS certified canopy/cab

– 12V power outlets, interior/exterior

– Pedals, raised, foot, brake/inching, accelerator

– Lever, parking brake

– Cup holders (2)

– CB radio clip, phone holder

– Door release, internal (left and right)

– Hook, large, coat and hard hat

– Floormat, heavy duty, easy clean

– Mirrors, (2) external breakaway, (1) internal

– Operator station on isolation mounts

– Steering wheel, spinner knob, horn in center

– Seat belt, orange, retractable, 51 mm (2 in)

– Storage, personal (trays [3], seat pocket)

– Steering column, tilt adjusted

– Column mounted multi function control: lights, roading, wipers, self cancelling turn signals

– Quick coupler switch, in cab

- Cab

-

OTHER

- Scheduled Oil Sampling (S·O·S℠) ports, engine oil and hydraulic oil

- Recovery hitch with pin

- Paint, Electro-Coat primer, gloss topcoat

- Machine lifting/tie down points

- Lockable, fuel cap, HVAC filters, nose cone

- Lockable main and side engine enclosures

- Loader arm safety brace

- Ground level easy access daily service points

- Fenders, front and rear

-

POWER TRAIN

- Fuel pump, priming (manual)/water separator/drain

- Engine oil, ECO drain tap and hose

- Engine, auto idle shutdown, hibernation mode

- Drive shaft, sealed for life, universal joints

- Coolant, extended life, –36° C (–33° F)

- Closed circuit breather

- Axles, heavy duty, frame mounted with outboard planetary reduction

- Air cleaner, two stage filter, with in cab audio/visual indicator on display

- Cat C2.8 engine

– Diesel particulate filter (Fit for Life) or muffler (Dependent on regional regulations.)

– Fuel, diesel, ultra low or low Sulphur (Dependent on regional regulations.)

– Hydrostatic transmission, two speed, with inching function, “shift on the go”

– Power train mode, hystat - Emissions compliant, two options (Dependent on regional regulations.)

– U.S. EPA Tier 4 Final and EU Stage V

– U.S. EPA Tier 3 and EU Stage IIIA equivalent

-

ELECTRICAL

- Work tool wiring harness, (3) in cab switches

- Push to start

- Lighting packages, multiple; front, rear, engine bay (LED or HAL)

-

HYDRAULICS

- Quick disconnect auxiliary hydraulics

- Reversing fan

- Ride Control or load check valves (Dependent on regional regulations.)

- Connect under pressure and case drain

- Caterpillar Bio HYDO Advanced hydraulic oil

- Auxiliary flow, single standard (3) valve, single high flow (3) valve, dual high flow (4) valve

-

OPERATOR STATION

- USB ports (2), interior

- Sun visor, rear perforated

- Storage, lockable box or lockable cooled box

- Soft touch keypad options, 8 or 16 button

- Secondary display, front or rear view camera

- Seat packages; deluxe or premium

- Seat belt options, multiple

- Radio, FM or digital audio broadcast

- Phone holder, spring loaded

- Mirrors (2) electronically adjustable, heated external, plus lower parabolic mirror

- Joystick, seat mounted, multifunction

- Interior light, door activated

- FNR, twin auxiliary roller, continuous flow, differential lock, horn

- Doors, sliding windows (left and right)

- Air Conditioning, automatic temperature control (ATC)

-

OTHER

- Rotary sensors (snubbing, kickouts, parallel)

- Couplers, vertical (SSL), horizontal (HPL-V, HPL-A)

-

POWER TRAIN

- Power train mode, utility (includes keypad)

- Hydrostatic transmission, 3-speed, “shift on the go”, secondary steering and boosted brakes

- Fuel pump, priming (Higher regulated countries), electric (Dependent on regional regulations.)

- Creep and throttle lock function

- Cold start – jacket water heater, bypass valve

- Antifreeze, extended life coolant, –50° C (–58° F)

-

$59,500 2021 Cat 272D3XE

-

$193,000 2022 Cat 315-07

-

2022 Cat D8T

-

$98,500 2019 Cat D3K2LGP

-

2022 Cat D8T

-

Browse All Used Equipment Inventory

View More

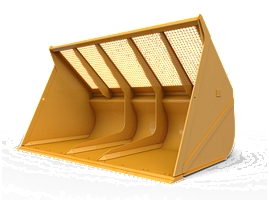

Buckets - Loader: 17.2 m³ (22.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 17.2 m³ (22.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 2.3m³ (3yd³) Material Handling Bucket for Wheel Loaders

Buckets - Loader: 2.3m³ (3yd³) Material Handling Bucket for Wheel Loaders  Buckets - Loader: 14.5 m³ (19 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14.5 m³ (19 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 14 m³ (18.25 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14 m³ (18.25 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 14.5 m³ (19 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14.5 m³ (19 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 11.9 m³ (15.5 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 11.9 m³ (15.5 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 11.9 m³ (15.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 11.9 m³ (15.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 14 m³ (18.25 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14 m³ (18.25 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only

Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only  Buckets - Loader: 5.0 m3 (6.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 5.0 m3 (6.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only

Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only  Buckets - Loader: 4.2 m3 (5.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 4.2 m3 (5.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only

Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only  Buckets - Loader: 3.8 m3 (5.0 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.8 m3 (5.0 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.5 m3 (4.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.5 m3 (4.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.5 m3 (4.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.5 m3 (4.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.5 m3 (4.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only

Buckets - Loader: 3.5 m3 (4.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only