Pipelayers

PL72 Pipelayer

-

Engine ModelCat® C9.3 ACERT™

-

Engine ModelCat C9.3

-

Flywheel Power212 hp

-

Flywheel Power211 hp

Engine

- Engine Model

- Cat® C9.3 ACERT™

- Engine Model

- Cat C9.3

- Flywheel Power

- 212 hp

- Flywheel Power

- 211 hp

- Net Power

- 211 hp

- Net Power

- 214 mhp

- Emissions

- U.S. EPA Tier 4 Final/EU Stage V/Korea Tier 4 Final or UN ECE R96 Stage IIIA equivalent to U.S. EPA Tier 3/EU Stage IIIA

- Fuel Tank

- 109.6 gal (US)

- DEF Tank

- 4.5 gal (US)

- Note

- Rated speed 2,000 rpm. Net power advertised is the power available at the flywheel when the engine is equipped with fan, air cleaner, muffler, and alternator. Net power is tested per ISO 9249:2007 and SAE J1349:2011.

- Note

- All non-road Tier 4 Interim and Final, Stage IIIB, Stage IV, Stage V, Japan 2014 and Korea Tier 4 Final diesel engines are required to use only ultra-low sulfur diesel (ULSD) fuels containing 15 ppm (mg/kg) sulfur or less. Biodiesel blends up to B20 (20%

- Bore

- 4.5 in

- Bore

- 4.5 in

- Note

- Diesel Exhaust Fluid (DEF) used in Cat Selective Catalytic Reduction (SCR) systems must meet the requirements outlined in the International Organization for Standardization (ISO) standard 22241.

- Stroke

- 5.9 in

- Stroke

- 5.9 in

- Displacement

- 567.5 in3

- Displacement

- 567.5 in³

- Engine Power

- 257 hp

- Engine Power

- 255 hp

- Emissions

- U.S. EPA Tier 4 Final/EU Stage IV or U.S. EPA Tier 3/EU Stage IIIA equivalent

- Engine Power

- 258 hp

- Net Power

- 212 hp

- Net Power

- 215 hp

- Net Power

- 246 hp

- Net Power

- 249 hp

- Engine Power

- 255 HP

- Engine Power

- 258 HP

- Engine Power

- 257 HP

- Net Power

- 246 HP

- Net Power

- 249 HP

Weights

- Lift Capacity

- 90000 lb

- Operating Weight

- 68945 lb

- Shipping Weight

- 59846 lb

- Shipping Weight

- 59846 lb

- Operating Weight

- 68945 lb

Transmission

- 1 Forward

- 2.3 mph

- 1 Forward

- 2.3 mile/h

- 2 Forward

- 4.1 mph

- 2 Forward

- 4.1 mile/h

- 3 Forward

- 7.1 mph

- 3 Forward

- 7.1 mile/h

- 1 Reverse

- 3.0 mph

- 1 Reverse

- 3 mile/h

- 2 Reverse

- 5.2 mph

- 2 Reverse

- 5.2 mile/h

- 3 Reverse

- 9.0 mph

- 3 Reverse

- 9 mile/h

- Drawbar Pull

- 86000 lb

- Drawbar Pull

- 49800 lb

- Drawbar Pull

- 26800 lb

Undercarriage

- Track Gauge

- 90 in

- Grouser Height

- 2.6 in

- Track Rollers

- 8

- Shoes

- 45

- Pitch

- 8.0 in

- Shoe Width

- 30 in

- Carrier Rollers

- 1

- Grouser Height

- 2.6 in

- Pitch

- 8 in

- Shoes

- 45

- Track Rollers

- 8

- Track Gauge

- 90 in

- Track on Ground

- 10.7 ft

- Ground Contact Area

- 8406 in²

- Ground Pressure

- 8.2 psi

- Shoe Width

- 30 in

- Ground Clearance

- 14.6 in

- Oscillation at Front Idler

- 6.4 in

- Ground Clearance

- 14.6 in

Pipelaying Equipment

- Lift Capacity

- 90000 lb

Components

- 6

- 2004 lb

- 7

- 2562 lb

- Components

- Upper Boom Block

- Lower Boom Block

- 55 lb

- Components

- Load Block

- Hook Block

- 338 lb

- Hook Block

- 338 lb

- Lower Boom Block

- 55 lb

Pipelayer Equipment

- Pullmaster Hydraulic Winches

- 180.1 ft

- Pullmaster Hydraulic Winches

- 180.1 ft

- Pullmaster Hydraulic Winches

- 60.85 ft/min

- Pullmaster Hydraulic Winches

- 148.0 ft

- Pullmaster Hydraulic Winches

- 180.1 ft

- Pullmaster Hydraulic Winches

- 8.5 in

- Pullmaster Hydraulic Winches

- 15.5 in

- Pullmaster Hydraulic Winches

- 10 in

- Pullmaster Hydraulic Winches

- 0.75 in

- Pullmaster Hydraulic Winches

- 180.1 ft

- Pullmaster Hydraulic Winches

- 180.1 ft

- Pullmaster Hydraulic Winches

- 8.5 in

- Pullmaster Hydraulic Winches

- 15.5 in

- Pullmaster Hydraulic Winches

- 10 in

- Pullmaster Hydraulic Winches

- 0.75 in

- Pullmaster Hydraulic Winches

- 148 ft

- Pullmaster Hydraulic Winches

- 180.1 ft

- Pullmaster Hydraulic Winches

- 165 ft

- Pullmaster Hydraulic Winches

- 131.9 ft

- Pullmaster Hydraulic Winches

- 165 ft

- Pullmaster Hydraulic Winches

- 165 ft

- Pullmaster Hydraulic Winches

- 144.4 ft/min

- Pullmaster Hydraulic Winches

- 60.85 ft/min

Dimensions (Approximate)

- Width

- 10 ft

- Width

- 17.65 ft

- Width

- 12.04 ft

- Width

- 11.88 ft

- Track Gauge

- 7.51 ft

- Length

- 12.17 ft

- Machine Height

- 8.53 ft

- Height

- 11.25 ft

- Boom Height

- 22.24 ft

- Boom Height

- 26.28 ft

- Track Gauge

- 7.51 ft

- Width of Tractor

- 10.00 ft

- Width of Tractor

- 11.88 ft

- Width of Tractor

- 12.04 ft

- Width of Tractor

- 17.65 ft

- Machine Height

- 8.53 ft

- Length of Track on Ground

- 12.17 ft

- Operating Length

- 15.68 ft

- Height of Machine

- 11.25 ft

- Grouser Height

- 2.6 in

- Ground Clearance

- 1.41 ft

- Drawbar Height

- 2.10 ft

- Drawbar

- 2.1 ft

- Ground Clearance

- 1.41 ft

- Grouser Height

- 2.6 in

- Operating Length

- 15.68 ft

Service Capacities

- Fuel Tank

- 109.6 gal

- Fuel Tank

- 109.6 gal (US)

- Cooling System

- 13.4 gal (US)

- Hydraulic Tank Oil

- 26.4 gal (US)

- Engine Crankcase

- 6.5 gal (US)

- Final Drive

- 3.6 gal (US)

- Power Train Oil System

- 39.1 gal (US)

- Diesel Engine Fluid

- 4.5 gal (US)

- Winch Case

- 3 gal

- Winch Case

- 3 gal

- Winch Case

- 3 gal (US)

- Winch Case

- 3 gal (US)

Air Conditioning System

- Air Conditioning

- The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 2.5 kg of refrigerant which has a CO2 equivalent of 3.575 metric tonnes.

Standards

- Brakes

- Brakes meet the standard ISO 10265:2008

- ROPS

- ROPS (Rollover Protection Structure) meets the standard ISO 3471:2008

- Brakes

- Brakes meet the standard ISO 10265:2008

- ROPS

- ROPS (Rollover Protection Structure) meets the standard ISO 3471:2008

Operating Specifications

- Lift Capacity

- 90000 lb

- Lift Capacity

- 90000 lb

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

POWER TRAIN

- Cat C9.3 diesel engine: Electronic Unit Injection (EUI) Aftertreatment Meets Tier 4 Final/ Stage V or Tier 3/Stage IIIA equivalent emission standards, depending on region of sale.

- Aftercooler, air-to-air (ATAAC)

- High performance single plane cooling system

- Coolant, extended life with protection to -37 C (-34F)

- 24V electric start

- Zero speed hydraulic fan, reversing and hydraulically driven, electronically controlled

- Filter, air with electronic service indicator

- Final drives: Four double reduction planetary

- Fuel priming pump, electric

- Parking brake, electronic

- Precleaner, strata-tube dust ejector

- Prescreener

- Starting aid, ether

- Torque divider

- Transmission, electronically controlled 3-speed Powershift

- Wastegate turbocharger

- Water separator

-

OPERATOR ENVIRONMENT

- Rear Vision Camera

- Armrest, adjustable

- Deactivation switch, hydraulic controls

- Advisor operator interface: Electronic monitoring system, Diagnostic service information, Operator preferences

- ROPS

- Decelerator pedal

- Dual brake pedal

- Seat belt, retractable

- Load Moment Indicator (LMI)

- Heater and ventilation

- Differential steering control, with touch shift

- Storage compartment

-

PIPELAYING EQUIPMENT

- Block and hook with latch

- Counterweights, extendible segmented

- Winches, hydraulic actuated and electronically controlled

-

ELECTRICAL

- Alarm, backup

- Batteries, four maintenance free heavy duty

- Converter, 12V, 10 amp with one outlet

- Horn, forward warning

- Lights, two front, two rear

- Starting receptacle

- Machine disconnect switch

- Machine diagnostic connector

- Boom and counterweight limit switch

-

UNDERCARRIAGE

- Carrier roller

- Track roller frames

- Hydraulic track adjusters

- Master links, two piece

- Non-suspended undercarriage

- Rollers and idlers, lifetime lubricated

- Sprocket rim segments, replaceable

- Track guiding guards

- Medium service grouser 760 mm (30 in) Sealed and lubricated track (48 section)

-

OTHER STANDARD EQUIPMENT

- Bumper, front with towing device

- Drawbar, heavy duty

- Ecology drains: Engine oil, coolant, hydraulic oil, torque converter, fuel tank, power train case and transmission

- Enclosures, perforated engine

- Hood, perforated

- Bottom guards, hinged

- Guard, hinged radiator

- Hydraulics, independent steering and work tool pumps

- Hydraulic system, electronically activated for hook, boom and counterweight control

- Oil cooler, hydraulic

- Product Link ready

- S-O-S sampling ports

- Steering, electronically controlled power differential

- Vandalism protection for fluid compartments

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

OPERATOR ENVIRONMENT

- Cab with air conditioning, heat and 150 amp alternator

- OROPS with heat and 150 amp alternator

- Cloth air seat

- Deluxe seat

- Vinyl seat

- Heated seat

-

UNDERCARRIAGE

- Arctic rollers

- Standard rollers

-

TECHNOLOGY PRODUCTS

- Product Link

-

PIPELAYING EQUIPMENT

- Boom and cables 6.1 m (20 ft)

- Boom and cables 7.3 m (24 ft)

-

OTHER OPTIONAL EQUIPMENT

- CE Certification

-

$59,500 2021 Cat 272D3XE

-

$193,000 2022 Cat 315-07

-

2022 Cat D8T

-

$98,500 2019 Cat D3K2LGP

-

2022 Cat D8T

-

Browse All Used Equipment Inventory

View More

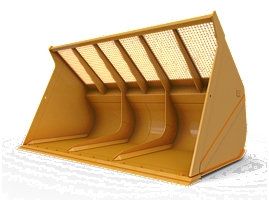

Buckets - Loader: 17.2 m³ (22.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 17.2 m³ (22.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 2.3m³ (3yd³) Material Handling Bucket for Wheel Loaders

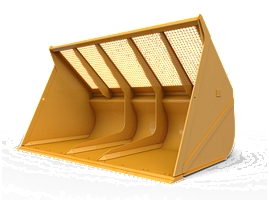

Buckets - Loader: 2.3m³ (3yd³) Material Handling Bucket for Wheel Loaders  Buckets - Loader: 14.5 m³ (19 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14.5 m³ (19 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 14 m³ (18.25 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14 m³ (18.25 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 14.5 m³ (19 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14.5 m³ (19 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 11.9 m³ (15.5 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 11.9 m³ (15.5 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 11.9 m³ (15.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 11.9 m³ (15.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 14 m³ (18.25 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14 m³ (18.25 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only

Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only  Buckets - Loader: 5.0 m3 (6.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 5.0 m3 (6.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only

Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only  Buckets - Loader: 4.2 m3 (5.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 4.2 m3 (5.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only

Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only  Buckets - Loader: 3.8 m3 (5.0 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.8 m3 (5.0 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.5 m3 (4.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.5 m3 (4.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.5 m3 (4.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.5 m3 (4.5 yd3) Fusion™ Coupler Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.5 m3 (4.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only

Buckets - Loader: 3.5 m3 (4.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge, 938 Only