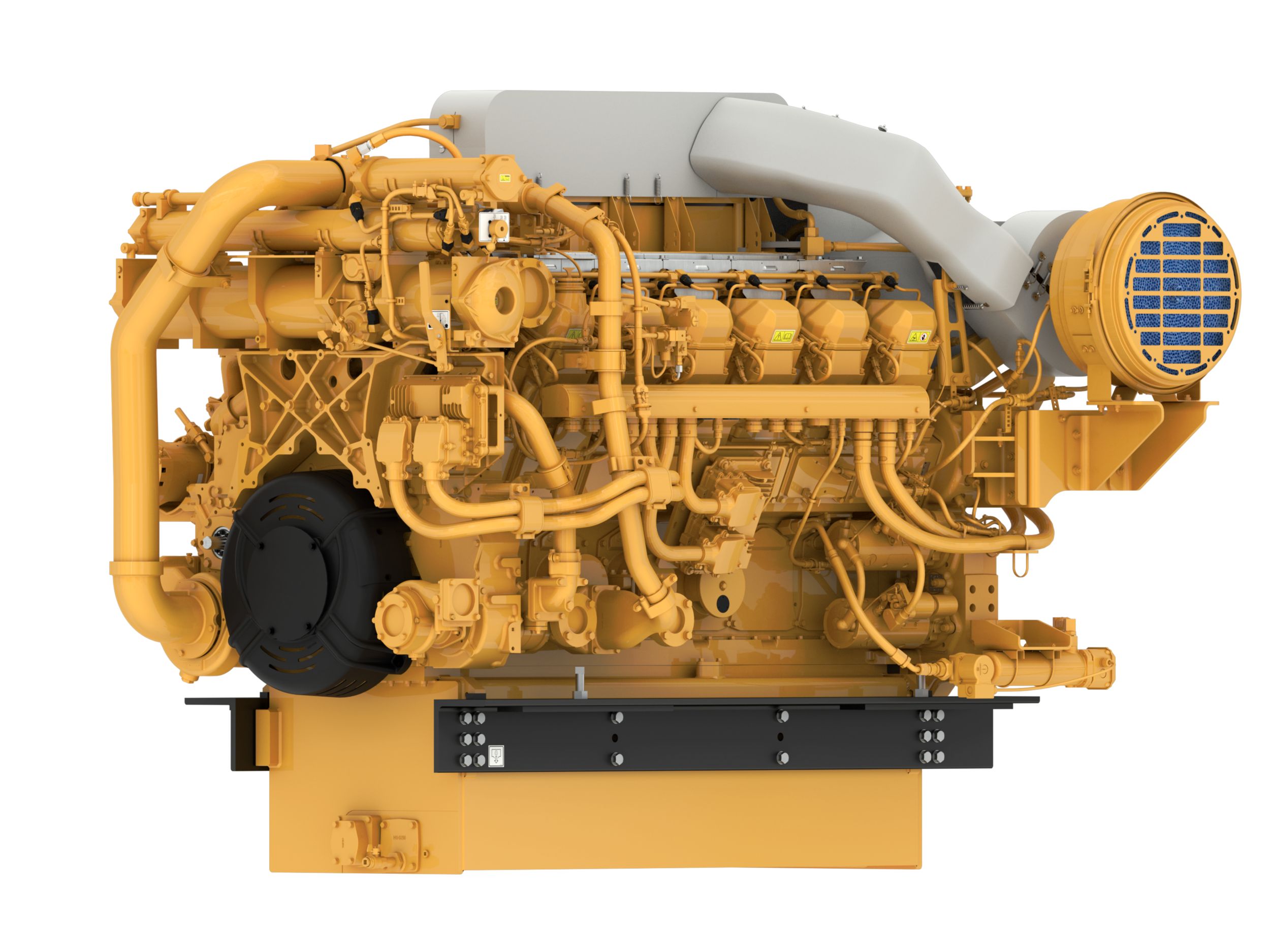

Commercial Propulsion Engines

3512C

-

Power Range1280-2551 bhp (955-1902 bkW)

-

Power Range1281 - 2552 bhp

-

Continuous Ratings1500.0 bhp

-

Heavy Duty Ratings1575.0 bhp

- Power Range

- 1280-2551 bhp (955-1902 bkW)

- Power Range

- 1281 - 2552 bhp

- Continuous Ratings

- 1500.0 bhp

- Heavy Duty Ratings

- 1575.0 bhp

- Maximum Continuous Ratings

- 1650.0 bhp

- Speed Range

- 1200 rpm, 1600 rpm, 1800 rpm

- Speed Range

- 1200 - 1800 rpm

- Emissions

- IMO II, EU IW

- Emissions

- IMO II, China Stage II

- Aspiration

- TTA

- Aspiration

- Twin Turbocharged Aspirator

- Bore

- 6.69 in

- Bore

- 6.69 in

- Stroke

- 7.48 in

- Stroke

- 7.48 in

- Displacement

- 3161.0 in3

- Stroke

- 8.46 in

- Displacement

- 3161 in³

- Displacement

- 3574 in³

- Rotation from Flywheel End

- Counterclockwise or Clockwise

- Configuration

- V 12, 4-Stroke-Cycle Diesel

- Minimum Dry Weight

- 14400.0 lb

- Minimum Length

- 102.0 in

- Minimum Height

- 75.0 in

- Minimum Width

- 80.2 in

- Maximum Length

- 102 in

- Maximum Height

- 75 in

- Maximum Width

- 80.2 in

- Minimum Dry Weight

- 14400 lb

- Minimum Height

- 75 in

- Minimum Length

- 102 in

- Minimum Width

- 80.2 in

- Maximum Dry Weight

- 16340 lb

- Maximum Dry Weight

- 16340 lb

- Length

- 111.1 in

-

Air Inlet System

- Separate circuit aftercooler core, corrosion resistant coated (air side)

- Powercore air cleaner

-

Control System

- Dual Caterpillar A4 Electronic Engine Control with Electronic Unit Injector Fuel System

- Rigid Wiring Harness (10 amp DC power required to drive Electronic Engine Control Module)

-

Exhaust System

- 3500C engines:

-

Fuel System

- Fuel transfer pump

- Electronically Controlled Unit Injectors

-

Instrumentation

- Electronic service meter, instrument panel (24V), start/stop switch, emergency stop button, maintenance due light, diagnostic light, warning light, maintenance clear switch, start motor magnetic switch, 15 and 3A breakers

- Graphical Unit (Color Marine Power Display) for analog or digital of:

-

Lube System

- Crankcase breather groups, Top mounted

- Oil filler and dipstick, LH or RH

- Oil pump, gear type

- 250 or 1000 hour sump oil pan

-

Mounting System

- Rails, engine mounting, ledge type, 203 mm x 203 mm (8 in x 8 in) or Front Trunnion

-

Power Takeoffs

- Accessory drives: Lower RH, lower LH

- Front housing, two-sided

-

Protection System

- A4 Electronic Monitoring System provides customer programmable engine derating strategies to protect against adverse operating conditions

- Emergency stop push button (located in Electronic Instrument Panel)

- Safety shutoff protection:

-

General

- Vibration damper and guard

- Lifting eyes

- NOTE: Engines for heat exchanger cooling do NOT include heat exchange

-

Flywheel and Flywheel Housing

- Flywheel, SAE No. 00, 183 teeth

- Flywheel housing, SAE No. 00

-

Cooling System

- Oil cooler

- Thermostats and housing, Full open temperature 92 C (198 F)

- Jacket water pump, gear driven, centrifugal

- Auxiliary fresh water pump

- Aftercooler system: If using glycol, up to maximum 20% glycol concentration is allowed

-

Air Inlet System

- Air Inlet Adapters

-

Charging System

- Battery Chargers

- Charging Alternator

-

Control System

- Throttle Control

-

Cooling System

- Coolant Shunt Tank

- Cooling System Options

-

Exhaust System

- Flexible Fittings

- Elbows

- Flanges

- Flange and Exhaust Expanders

- Mufflers

-

Fuel System

- Fuel Cooler Heat Exchanger - Sea Water

- Primary Fuel Filter

- Fuel Level Switch

- Rigid Fuel Lines

- Flexible Fuel Lines

-

Instrumentation

- Communication Modules

- Color Marine Power Display System

- Pilot House Instrument Panels

- Marine Gear Sensors

-

Lube System

- Sump Pumps

- Lubricating Oil

-

Power Take-Offs

- Stub Shafts

- Crankshaft Pulleys

- Damper Guard

- Flexible Coupling and Guards

-

Marine Society Requirements

- Green Passport Documentation

- Spray Shielding

-

Protection System

- Shutoff and Alarm Contactors

-

Special Appearance Packages

- Special Appearance Packages with Chrome Covers

- Yacht Class Finish

-

Starting System

- Air Starting Motor Options

- Battery Sets - 24 Volt - Dry

- Battery Rack

-

Mounting System

- Engine Supports

- Vibration Isolation Mountings

-

Packing

- Shrink Wrap Protection

- Storage Preservation with Glycol Solution/Vapor Corrosion Inhibitor

- Export Boxing

- Export Packaging