Gas Compression Engines

G3606 A4 Gas Engine

-

Minimum Rating1875.0 bhp

-

Maximum Rating2065 BHP

-

Maximum Rating2010.0 bhp

-

EmissionsNSPS Site Compliant Capable

Engine Specifications

- Minimum Rating

- 1875.0 bhp

- Maximum Rating

- 2065 BHP

- Maximum Rating

- 2010.0 bhp

- Emissions

- NSPS Site Compliant Capable

- Emissions

- NSPS Site Compliant Capable

- Displacement

- 7762 in³

- Displacement

- 7762.0 in3

- Minimum Rating

- 1900 BHP

- Compression Ratio

- 9.2:1

- Compression Ratio

- 9.2:1 Gen 1 (7:6:1 Gen 2)

- Aspiration

- Turbocharged-Aftercooled

- Aspiration

- Turbocharged-Aftercooled

- Rotation

- Counterclockwise

- Rotation from Flywheel End

- Counterclockwise

- Flywheel Teeth

- 255

- Flywheel Teeth

- 255

- Weight

- 36883 lb

- Oil Change Interval

- 5000 hours

- Oil Change Interval

- 5000 hours

- Ignition

- Electronic (ADEM™ A4)

- Stroke

- 11.8 in

- Stroke

- 11.8 in

- Bore

- 11.8 in

- Bore

- 11.8 in

- Length

- 167.33 in

- Width

- 86.17 in

- Height

- 116.16 in

Capacity for Liquids

- Cooling System

- 124.0 gal

- Cooling System

- 124 gal (US)

- Lube Oil System

- 187.0 gal

- Lube Oil System

- 187 gal (US)

-

Air Inlet System

- Air cleaner — standard-duty inlet air adapter

-

Control System

- A4 control system — provides electronic governing integrated with air/fuel ratio control and individual cylinder ignition timing control

- Electrical system and instrumentation certified for Class I, Division 2, Group D hazardous location. Includes entire ADEM A4 system and optional control panel.

-

Cooling System

- Jacket water pump

- Jacket water thermostats and housing

- Aftercooler/oil cooler pump

- Aftercooler/oil cooler thermostats and housing

- Two-stage aftercooler

- Jacket water heater connections

- Standard ANSI connections

-

Exhaust System

- Dry exhaust manifolds

- Single vertical outlet adapter

- Stainless steel encapsulated insulation

-

Flywheels and Flywheel Housing

- SAE standard rotation

-

Fuel System

- Gas admission valves -- electronically controlled fuel supply pressure

-

Ignition System

- A4 control system — senses individual cylinder detonation and controls individual cylinder timing

-

Lube System

- Crankcase breathers (top mounted)

- Oil cooler

- Oil filter

- Oil pan drain valves -- front and rear

-

Mounting System

- Engine mounting feet (four total)

-

Protection

- Electronic shutoff system with purge cycle

- Crankcase explosion relief valves

- Gas shutoff valve

-

Starting System

- Air starting system

-

General

- Paint — Cat yellow

- Vibration dampers

-

Air Inlet System

- Heavy-duty air cleaner with precleaners

-

Charging System

- 35 Amp & 65 Amp charging alternators – CSA approved

-

Exhaust System

- Flexible bellows adapters

- Exhaust expander

- Weld flanges

-

Fuel System

- Fuel filter

- Gas pressure regulator

- Flexible connection

-

Instrumentation

- LCD display panel

- Remote data monitoring and speed control

- Color HMI display

- Compatible with Cat® Electronic Technician (ET) and Data View

- Modbus and Ethernet capable

-

Lube System

- Air or electric motor-driven prelube

- Duplex oil filter

- RH Service

- Lube oil makeup system

-

Mounting System

- Mounting plates (set of four)

- Extra mounting feet (set of two)

- Extra mounting plates (set of two)

-

Power Take-Offs

- Front stub shafts

-

Starting System

- Air pressure reducing valve

-

General

- Engine barring device

- Damper guard

Buckets - Loader: 2.7m³ (3.5yd³) Material Handling Bucket for Wheel Loaders

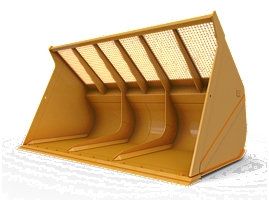

Buckets - Loader: 2.7m³ (3.5yd³) Material Handling Bucket for Wheel Loaders  Buckets - Loader: 14.5 m³ (19 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14.5 m³ (19 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 17.2 m³ (22.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 17.2 m³ (22.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 14 m³ (18.25 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14 m³ (18.25 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 14 m³ (18.25 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14 m³ (18.25 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 14.5 m³ (19 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 14.5 m³ (19 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 11.9 m³ (15.5 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 11.9 m³ (15.5 yd³) Fusion™ Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 11.9 m³ (15.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge

Buckets - Loader: 11.9 m³ (15.5 yd³) pin on Light Material Bucket with Bolt-On Cutting Edge  Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 5.0 m3 (6.5 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 5.0 m3 (6.5 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 5.0 m3 (6.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 4.2 m3 (5.5 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 4.2 m3 (5.5 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 4.2 m3 (5.5 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.8 m3 (5.0 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.8 m3 (5.0 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.8 m3 (5.0 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.5 m3 (4.6 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.5 m3 (4.6 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge