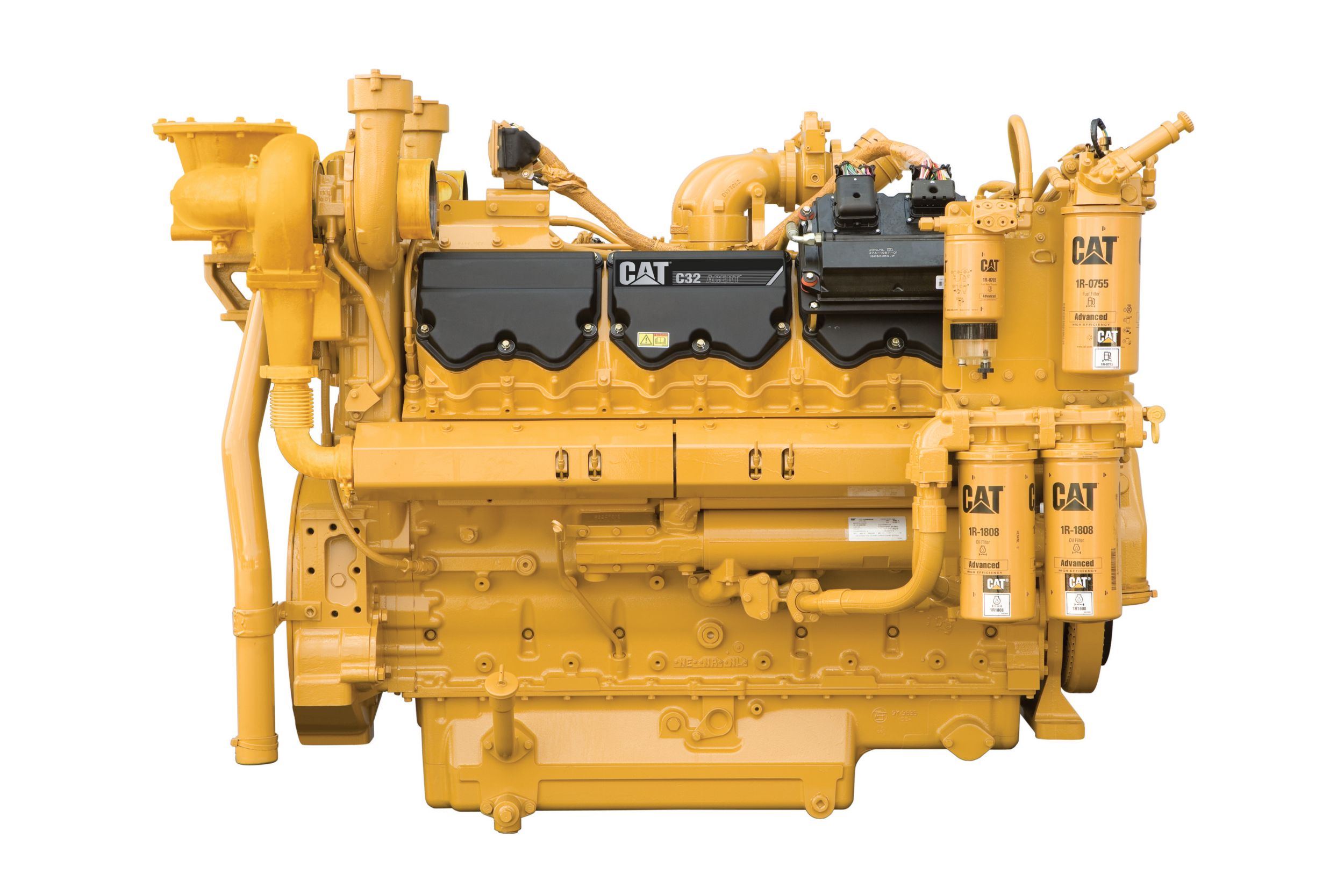

Land Drilling Engines and Generator Sets

C32 ACERT Land Mechanical Drilling Engine

-

Minimum Rating800.0 bhp

-

Maximum Rating1500 BHP

-

Maximum Rating1500.0 bhp

-

EmissionsU.S. EPA Non-road Tier 2

Engine Specifications

- Minimum Rating

- 800.0 bhp

- Maximum Rating

- 1500 BHP

- Maximum Rating

- 1500.0 bhp

- Emissions

- U.S. EPA Non-road Tier 2

- Emissions

- U.S. EPA Non-road Tier 2

- Displacement

- 1953 in³

- Rated Speed

- 2100.0 RPM

- Minimum Rating

- 800 BHP

- Bore

- 5.7 in

- Bore

- 5.7 in

- Stroke

- 6.4 in

- Stroke

- 6.4 in

- Displacement

- 1953.0 in3

- Rated Speed

- 2100 r/min

- Aspiration

- Turbocharged-Aftercooled

- Aspiration

- Turbocharged-Aftercooled

- Governor and Protection

- ADEM A3

- Engine Weight

- 5040.0 lb

- Engine Weight

- 5040 lb

- Oil Change Interval

- 250

- Rotation

- Counterclockwise

- Oil Change Interval

- 250

- Rotation from Flywheel End

- Counterclockwise

- Flywheel and Flywheel Housing

- SAE No. 0 or SAE No. 1

- Flywheel and Flywheel Housing

- SAE No. 0 or SAE No. 1

- Flywheel Teeth

- 136 (SAE 0), 113 (SAE 1)

- Flywheel Teeth

- 136 (SAE 0), 113 (SAE 1)

Capacity for Liquids

- Minimum Cooling System

- 14.5 gal (US)

Dimensions

- Length

- 75.5 in

- Length

- 75.5 in

- Width

- 85.0 in

- Width

- 58 in

- Height

- 52.0 in

- Height

- 52 in

-

Air Inlet System

- Quad turbocharger — 3 cylinder exhaust to each turbo

- Connections configured for ATAAC (Air-to-Air-Aftercooled)or remote heat exchanger

-

Control System

- ADEM A4 electronic control module

- Electronic governing, PTO speed control

- Customer programmable ratings

- Cold mode start strategy

- Automatic altitude compensation

- Automatic fuel temperature compensation

- Programmable low and high idle, and top engine speedlimit

- Electronic diagnostics and fault logging

- Engine monitoring system

- SAE J1939 broadcast (diagnostic and engine status)

-

Cooling System

- Gear-driven centrifugal jacket water pump — RH

- Integrated thermostat and housing

- Engine oil cooler

- Optional installed transmission oil cooler

-

Exhaust System

- Exhaust manifold — dry

- Two vertical exhaust outlets (front and rear)

-

Fuel System

- MEUI

- Fuel priming pump

- Fuel transfer pump

- Primary and secondary fuel filter — RH configured forremote mounting (installed RH on shipping plate)

-

Flywheels and Flywheel Housing

- SAE No. 0 or SAE No. 1 flywheel iron housing

- SAE No. 0 or SAE No. 1 flywheel

- Optional transmission adapter

-

Lube System

- Crankcase breather

- Oil filter — RH standard, optional LH or remote mountservice

- Oil level gauge — RH standard, optional LH or dualservice

- Oil filler — RH standard, optional LH or dual service

- Shallow oil pan, rear sump

-

Mounting System

- Trunnion front support

- Vertical and horizontal pads on rear flywheel housing

-

Protection System

- 24V electronic

- Engine overspeed with optional air shut-offs withindicators

- Low engine oil pressure

- Fuel filter restriction

- Fuel temperature

- High engine coolant temperature

- Low engine coolant temperature

-

General

- Vibration damper and optional guard

- Lifting eyes

- Optional customer wiring connector

- Service tool connector

- Paint — Cat yellow

-

Air Inlet System

- Air cleaner

- Air inlet adapters

- Turbocharger outlet adapters

- Air lines

-

Charging System

- Battery chargers

- Charging alternators

- Alternator mounting

- Circuit breakers and mountings

-

Cooling System

- Dry charge coolant conditioners

- Thermostat housing

- Coolant level sensor

- Radiator

- Blower fans

- Suction fans

- Fan adapters

- Fan drives

-

Emissions

- IMO certifications

-

Exhaust System

- Elbows

- Mufflers

-

Fuel Systems

- Electric fuel priming pump

-

Instrumentation

- Customer management device

- Interconnect harness

- Gauges and instrument panels

-

Lube System

- Oil pans

- Oil service side

- Oil level gauge

- Oil filters

- Lubricating oils

-

Mounting System

- Structural steel base

- Engine support — front

- Engine support — rear

-

Power Take-Offs

- Auxiliary drive

- Damper pulley

- Hydraulics gear pumps

-

Protection System

- Mechanical shutoffs

- Solenoid shutoffs

-

Starting System

- Electric starting motors – 12V, 24V

- Battery sets – 24V

- Battery cable

- Battery rack

- Starting aids

-

Transmission Arrangement

- Transmissions water lines

- Transmissions cooler