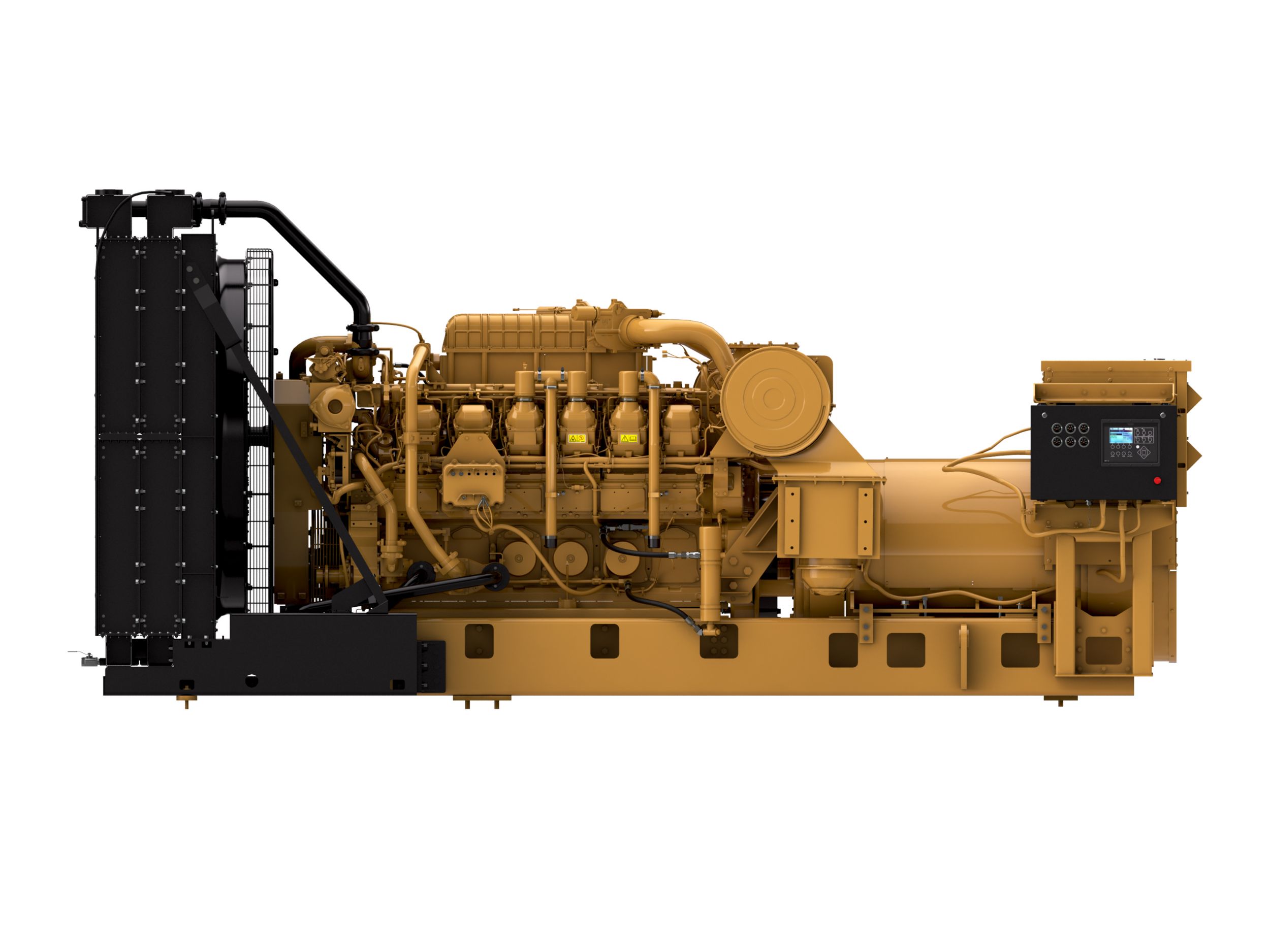

Land Electric-Drive Modules

3512C (HD) Land Electric-Drive Drilling Module

-

Minimum Rating1245.0 ekW

-

Minimum Rating1245 ekW

-

Maximum Rating1245.0 ekW

-

Maximum Rating1245 ekW

Engine Specifications

- Minimum Rating

- 1245.0 ekW

- Minimum Rating

- 1245 ekW

- Maximum Rating

- 1245.0 ekW

- Maximum Rating

- 1245 ekW

- Emissions

- U.S. EPA Nonroad Tier 2

- Emissions

- U.S. EPA Nonroad Tier 2

- Engine Control and Protection

- ADEM A3

- Generator

- SR4B

- Aspiration

- Turbocharged-Aftercooled

- Bore

- 6.69 in

- Stroke

- 8.5 in

- Displacement

- 3574.0 in3

- Fuel System

- EUI

- Oil Change Interval

- 500.0 hr

- Weight

- 29500.0 lb

- Generator Set Control

- EMCP 4.3

- Voltage

- 600

- Aspiration

- Turbocharged-Aftercooled

- Bore

- 6.69 in

- Displacement

- 3574 in³

- Engine Control and Protection

- ADEM A3

- Fuel System

- EUI

- Generator

- SR4B

- Generator Set Control

- EMCP 4.3

- Oil Change Interval

- 500 h

- Stroke

- 8.5 in

- Weight

- 29500 lb

Dimensions

- Width

- 93.9 in

- Length

- 310.2 in

- Length

- 310.2 in

- Width

- 93.9 in

Capacity for Liquids

- Lube Oil System

- 84.0 gal

- Cooling System

- 41.0 gal

- Cooling System

- 41 gal (US)

- Lube Oil System

- 84 gal (US)

-

Air Inlet System

- Corrosion-resistant aftercooler core

- Air Inlet shutoff

- Regular duty air cleaner

-

Control System

- ADEM A3 ECU, left-hand mounted

- Direct rack control 0-200 mADC, space heater and jacket water heater connection and controls or

- Cat Digital Voltage Regulator (DVR), includes reactive droop capability, 3-phase voltage sensing, kVAR/PF modes, RFI suppression, min/max exciter limiter and exciter diode monitor, space heater and jacket water heater connection and controls, temperature monitoring for 6 stator RTDs and 2 bearing RTDs via J1939

-

Cooling System

- Separate-circuit aftercooled

- Outlet controlled jacket water thermostat

- Jacket water pump - gear driven

- Dual outlet

- Aftercooler water pump - gear driven

- Aftercooler water thermostat

-

Exhaust System

- Dry exhaust manifold

- Dual turbochargers, water cooled bearings

- Exhaust adapter, 297 mm I.D. to 340 mm I.D. (11.7 in to 13.4 in)

- Weldable flange, 360 mm I.D. (14.2 in)

-

Flywheel and Housing

- SAE No. 00 flywheel

- SAE No. 00 flywheel housing

- SAE standard rotation

-

Fuel System

- Fuel filter simplex (LH) with priming pump (LH)

- Fuel transfer pump

- Fuel return line with flexible connection

- Electronic unit injectors

- Fuel priming pump

-

Instrumentation

- Emergency stop button

- Analog gauges:

- Service port connector

- Customer connection terminal blocks

-

EMCP 4.3 Control Panel

- 140 mm (5.5 in) Graphical Display

- Communication

- Controls

- Generator Set Protection

- Outputs

- Inputs

- Other Features

-

Lubrication System

- Crankcase breather

- Oil cooler

- Shallow oil pan

- Oil drain extension, 2 in NPT female connection

- Simplex oil filter

-

Mounting System

- 4.19 m (165 in) length, 412 mm (16.2 in) height tubes, 1.18 m (50.5 in) wide

- Viscous damper drive line coupler

-

Power take-offs

- Accessory drive

- Lower LH front (available for PTO usage)

- Front housing, two-sided

-

Protection System

- Engine alarms, derate, and shutdown in abnormal operation

-

Starting System

- TDI air starting motor, RH - 1034 kPa (150 psi)

- LH control air silencer

-

General

- Paint - Cat yellow

- Vibration damper and guard

- Lifting eyes

- Lift and cable two provisions

-

Air Inlet System

- Heavy duty air cleaner

- Remote air inlet adapter - rectangular

- Remote air inlet adapter - round

-

Control System

- Load sharing governor, 2301A

- Load sharing module

- Governor conversion to 0-200 mA direct rack control

-

Cooling System

- Radiator options:

- Coolant level sensor

- Coolant conditioner

-

Exhaust System

- Exhaust flexible fitting, 318 I.D. mm (12.5 in)

- Elbow, 305 mm (12 in)

- Muffler 305 mm (12 in), non spark arresting

- Muffler, 356 mm (14 in), spark arresting, includes companion flanges, clean-out box, and spark box

- Muffler, 305 mm (12 in), spark arresting, includes companion flanges, clean-out box, and spark box

-

Fuel System

- Custom fuel filter

- Primary fuel filter

- Primary fuel filter with water separator

-

Generator Attachments

- Barrel-mounted petroleum terminal box with air filter and pressure differential switch

- Barrel-mounted petroleum terminal box

- Current droop transformer

- Cable access box

- Low voltage extension box

- Current sensing transformers (3)

- Bearing temperature detectors

-

Instrumentation

- Communications module PL1000T

- Communications module PL1000E

- Thermocouples installed, one per cylinder

-

Lubrication System

- RH installed centrifugal oil filter

- Crankcase fumes disposal

- Oil level regulator

-

Mounting System

- 7.62 m (25 ft) outer base

- 9.14 m (30 ft) outer base

- 12.19 m (40 ft) outer base

- Package isolator supports (3), for mounting inner base to customer-supplied base

- Custom base

-

Power Take-off

- Alternator, 24V, 60A

- Crankshaft pulley

-

Protection System

- Explosion relief valves (3)

- Metal particle detector switch

- Metal particle detector with annunciator

-

Starting System

- Custom starting motor

- Air pressure regulator

-

General

- LH installed engine barring group

- Jacket water heater, UL recognized, 120-240V, single phase, 6 kW, LH and RH mounted

- Jacket water heater, UL recognized, 120-480V, single phase, 12 kW, LH and RH mounted

- Jacket water heater lines