Oil and Gas

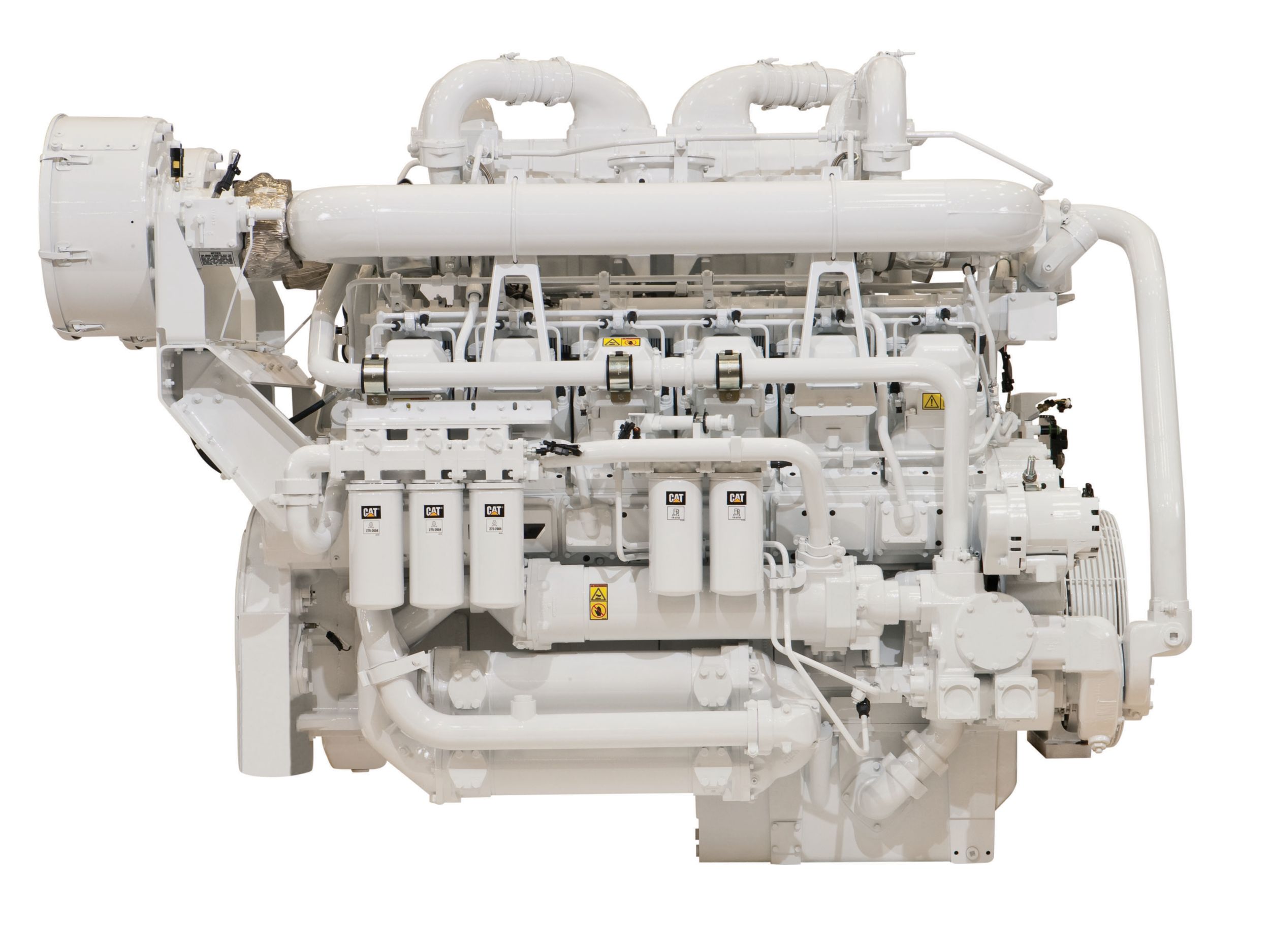

3512C (HD) Offshore Well Stimulation Engine

-

Maximum Rating2500 BHP

-

Displacement58.9 in³

-

Minimum Rating2150 BHP

-

AspirationTurbocharged-Aftercooled

General Specifications

- Maximum Rating

- 2500 BHP

- Displacement

- 58.9 in³

- Minimum Rating

- 2150 BHP

- Aspiration

- Turbocharged-Aftercooled

- Flywheel and Flywheel Housing

- SAE No. 0

- Flywheel Teeth

- 151

- Stroke

- 8.5 in

- Bore

- 6.7 in

Emissions

- Emissions

- IMO Tier II and EPA Marine Tier 2

Dimensions

- Length

- 113.8 in.

- Length

- 113.8 in

- Width

- 64.2 in.

- Width

- 64.2 in

- Height

- 86.1 in.

- Height

- 86.1 in

- Weight

- 14145.0 lb

- Weight

- 14145 lb

-

Air Inlet System

- Heavy-duty air cleaners (dual element/service indicator)

- Four center-mounted turbochargers

-

Control System

- Cat® ADEM A3 ECU — LH

- With electronic fuel injector fuel system (10 amp DC power required to drive electronic engine control module)

-

Cooling System

- Separate Circuit SCAC system

- Torque converter connections

- Thermostats and housing, jacket and separate circuit water pump, gear-driven centrifugal

-

Exhaust System

- Land well service engine

- Exhaust manifold, dry, slip joint with stainless steel wire seal

- Four turbochargers with watercooled bearings (center mounted)

- Exhaust outlet, dual 203 mm (8 in) round flange

-

Flywheel and Flywheel Housings

- Flywheel, SAE No. 0, 151 teeth

- Flywheel housing, SAE No. 0

-

Fuel System

- Primary fuel filter

- Fuel priming pump

- Fuel filter — RH spin-on type

- Fuel transfer pump

- Electronically controlled unit injectors

-

Instrumentation

- No standard instrumentation

- Optional, remote instrumentation available

- Service meter

-

Lube System

- Crankcase breather — top mounted

- Oil cooler

- Oil filler and dipstick — LH

- Oil pump

- Oil filter — RH spin-on type

- Rear sump oil pan — 250-hour change interval

- Oil pan drain valve — 1" NPT female connection

- Fumes disposal

- Scavenger pump

-

Mounting System

- Trunion front support

-

Power Take-Offs

- Accessory drive — lower LH

- Front housing — two-sided

-

Protection System

- ADEM A3 ECU system to provide customer programmable engine deration strategies to protect against adverse operating conditions

- Emergency stop logic inputs provided at 40-pin customer interface connection

- Dual air inlet shutoff

- Oil pressure monitor

-

General

- General

- Vibration damper and guard

- Lifting eyes

-

Charging System

- Charging alternators

-

Control System

- Local speed throttle control

- Throttle position sensors

- Governor conversion

-

Cooling System

- Coolant regulator conversion

- Water level switch gauge

- Coolant level sensors and coolant conditioner

-

Exhaust System

- Flexible exhaust fitting

- Elbows, flange, exhaust adapters

- Manifold and mufflers

-

Fuel Systems

- Flexible fuel lines

- Water/fuel separator

- Fuel level switch

-

Instrumentation

- Remote panel display and remote cylinder temperature display

- Gauges and instrument panels

-

Lube System

- Oil pans and filters

- Deep sump oil pan and front sump pan

-

Power Take-Offs

- Front crankshaft adapter

- Flywheel stub shaft

-

Protection System

- Sensors

- Shutoff controls

-

Starting System

- Air starting motors

- Electric starting motors

- Hydraulic starter

- Ether starting aids

- Battery sets — 24V

- Battery cable and battery rack

Buckets - Loader: 3.5 m3 (4.6 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.5 m3 (4.6 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.8 m3 (5.0 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.8 m3 (5.0 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.5 m3 (4.6 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.5 m3 (4.6 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.5 m3 (4.6 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.5 m3 (4.6 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.0 m3 (3.9 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.0 m3 (3.9 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 4.7m³ (6.2yd³) Iron Ore Bucket for Wheel Loaders

Buckets - Loader: 4.7m³ (6.2yd³) Iron Ore Bucket for Wheel Loaders  Buckets - Loader: 3.0 m3 (3.9 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.0 m3 (3.9 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 4.6m³ (6.0yd³) Grapple Bucket for Wheel Loaders

Buckets - Loader: 4.6m³ (6.0yd³) Grapple Bucket for Wheel Loaders