Oil and Gas

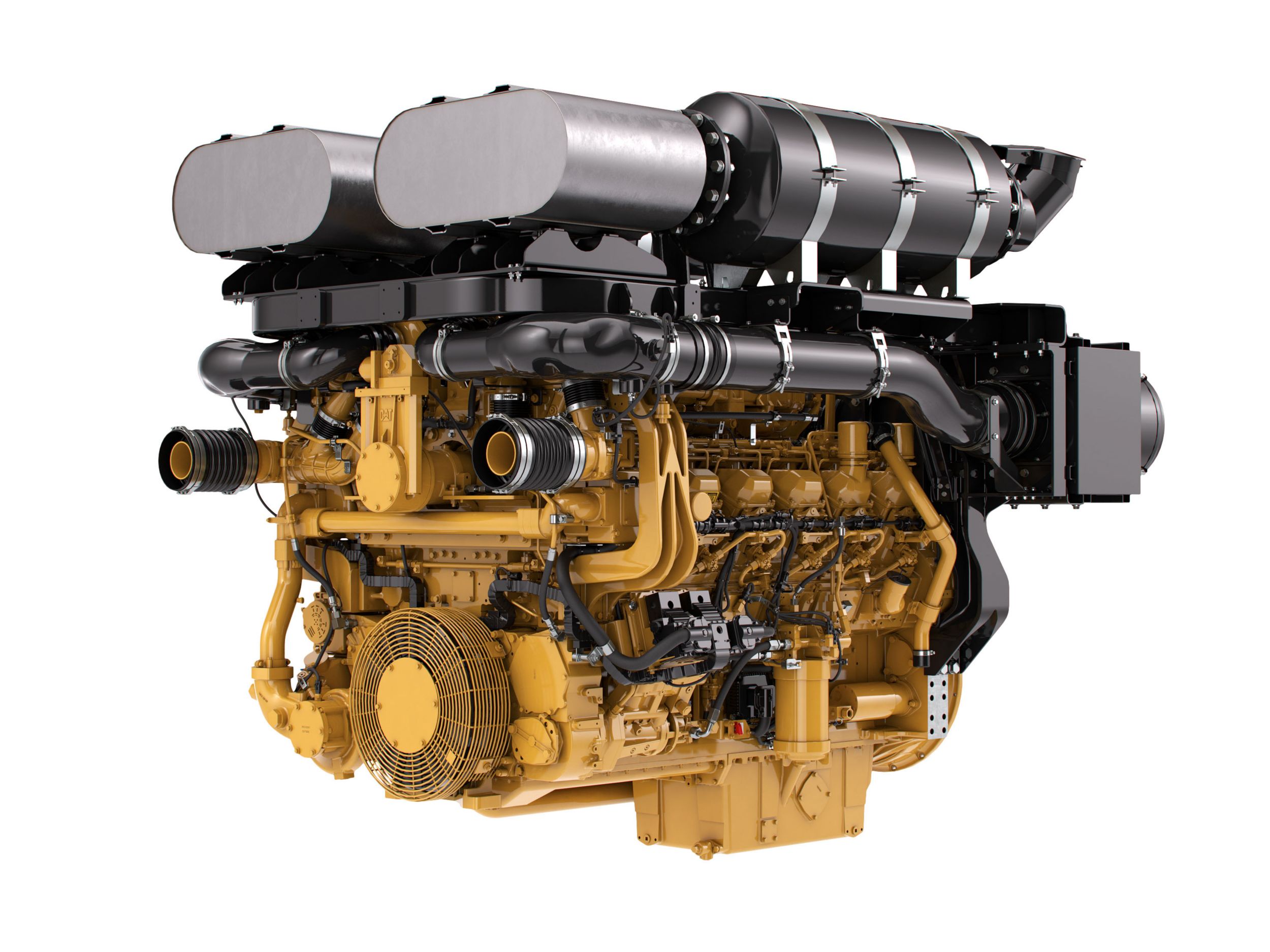

3512E Tier 4 Final Well Service Engine

-

Maximum Rating2500 BHP

-

Displacement3596 in³

-

Minimum Rating2250 BHP

-

AspirationTurbocharged-Aftercooled

General Specifications

- Maximum Rating

- 2500 BHP

- Displacement

- 3596 in³

- Minimum Rating

- 2250 BHP

- Aspiration

- Turbocharged-Aftercooled

- Flywheel and Flywheel Housing

- SAE No. 0

- Flywheel Teeth

- 151

- Stroke

- 8.5 in

- Bore

- 6.7 in

Emissions

- Emissions

- Non-Road Mobile EPA Tier 4 Final

Dimensions

- Length

- 123.0 in.

- Length

- 123 in

- Width

- 90.9 in.

- Width

- 90.9 in

- Height

- 104.0 in.

- Height

- 104 in

- Weight

- 15793.0 lb

- Weight

- 15793 lb

-

Air Inlet System

- Air-to-air aftercooled

- Air cleaners (single element w/service indicator)

-

Control System

- ADEM A4 ECU, LH

- With electronic fuel injector fuel system (10 amp DC power required to drive electronic engine control module)

-

Cooling System

- ATAAC

- Thermostats and housing, jacket water pump, gear-driven centrifugal (gear-driven centrifugal pumps)

-

Exhaust System

- Land Well Service Engine:

- Offshore Well Service Engine:

-

Flywheels & Flywheel Housing

- Flywheel, SAE No. 0, 151 teeth

-

Fuel System

- Secondary/tertiary fuel filters

- Fuel priming pump (electric)

- Common rail fuel system

- Fuel transfer pump

-

Lube System

- Crankcase breather — top-mounted

- Electric prelube

- Fumes disposal

- Oil cooler

- Oil filler and dipstick — LH

- Oil pump

- Oil filter — RH spin-on type

- Rear sump oil pan, 250-hour change interval

- Oil pan drain valve, 1" NPT female connection

- Oil scavenger pump

-

Mounting System

- Trunion front support

-

Power Take-Offs

- Accessory drive -- Lower LH/upper RH

- Front housing, two-sided

-

Protection System

- ADEM A4 ECU system to provide customer programmable engine deration strategies to protect against adverse operating conditions

- Emergency stop logic inputs provided at 40-pin customer interface connection

- Dual Air inlet shutoff

- Oil pressure monitor

-

General

- Paint, Cat yellow

- Vibration damper and guard

- Lifting eyes

- Hydraulic valve lash adjusters

- Power link engine monitoring

-

Air Inlet System

- Optional heavy-duty air cleaners (dual element/service indicator with precleaners)

- Four front-mounted turbochargers

-

Charging System

- Charging alternators

-

Control System

- Throttle position sensors

- Local speed throttle control

- Governor conversion

- Variable speed radiator fan control

-

Cooling System

- Coolant regulator conversion

- Water level switch gauge

- Coolant level sensors and coolant conditioner

- External transmission cooler connections

- Variable speed hydraulic fan pump

-

Emissions Certifications

- US EPA Tier 4 Final

-

Exhaust System

- Flexible exhaust fitting

- Elbows, flange, bellows, rain caps

- Industrial and residential mufflers (painted steel and stainless steel)

-

Fuel Systems

- Flexible fuel lines

- Primary fuel filter/fuel water separator

-

Instrumentation

- Remote panel display and remote cylinder temperature display

-

Lube System

- 500- hour deep sump oil pan (rear sump pan)

-

Power Take-Offs

- Flywheel stub shaft

- Front Crankshaft Adapter

-

Protection System

- Sensors

- Shutoff controls

-

Starting System

- Hydraulic starter

- Hydraulic starter - RH

- Dual hydraulic starter - LHR

- Manual engine barring device

-

General

- Air compressor

- Aftertreatment support package

Buckets - Loader: 3.5 m3 (4.6 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.5 m3 (4.6 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.8 m3 (5.0 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.8 m3 (5.0 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.5 m3 (4.6 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.5 m3 (4.6 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.5 m3 (4.6 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.5 m3 (4.6 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 3.0 m3 (3.9 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.0 m3 (3.9 yd3) Pin On Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 4.7m³ (6.2yd³) Iron Ore Bucket for Wheel Loaders

Buckets - Loader: 4.7m³ (6.2yd³) Iron Ore Bucket for Wheel Loaders  Buckets - Loader: 3.0 m3 (3.9 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge

Buckets - Loader: 3.0 m3 (3.9 yd3) Fusion™ Light Material Bucket With Bolt-On Cutting Edge  Buckets - Loader: 4.6m³ (6.0yd³) Grapple Bucket for Wheel Loaders

Buckets - Loader: 4.6m³ (6.0yd³) Grapple Bucket for Wheel Loaders